Carbide and ceramic inserts are two commonly used cutting tools in machining operations, each with its own unique properties and advantages. Understanding the differences between these inserts can help in selecting the most appropriate tool for specific applications. Composition: Carbide inserts are primarily composed of tungsten carbide, which is a hard compound consisting of tungsten and carbon atoms. Tungsten carbide is known for its exceptional hardness and wear resistance, making it an excellent choice for cutting tools. To enhance its properties, tungsten carbide is often combined with a binder material, typically cobalt. The cobalt binder improves the toughness and strength of the carbide, making it more resistant to chipping and fracturing during machining operations. Ceramic inserts, on the other hand, are made from various ceramic materials. Alumina (aluminum oxide) and silicon nitride are common ceramic materials used in inserts. These ceramics offer high hardness and excellent thermal stability. To further enhance their properties, ceramic inserts are typically reinforced with other materials, such as silicon carbide or whiskers, which improve their toughness and resistance to fracture. Properties: Carbide inserts are renowned for their hardness, wear resistance, and toughness. Tungsten carbide is one of the hardest materials used in machining, allowing carbide inserts to maintain their cutting edge for extended periods. Their excellent wear resistance ensures prolonged tool life, reducing the need for frequent tool changes. Carbide inserts are also known for their toughness, meaning they can withstand high cutting forces and are less prone to chipping or fracturing during machining operations. Ceramic inserts possess exceptional hardness, high-temperature resistance, and chemical stability. Ceramics are significantly harder than carbides, allowing them to withstand higher cutting speeds and offer superior wear resistance. These inserts also exhibit remarkable thermal stability, enabling them to perform in high-temperature cutting environments without losing their cutting edge. However, ceramics are generally more brittle than carbides, making them susceptible to chipping or fracturing under certain conditions. Careful handling and proper machining parameters are crucial to prevent damage to ceramic inserts. Applications: Carbide inserts

are widely used in various machining operations, including turning, milling, drilling, and threading. They are well-suited for cutting hard materials such as steels, stainless steels, cast iron, and some non-ferrous metals. Carbide inserts are preferred for high-speed machining due to their excellent heat resistance and ability to maintain their cutting edge at elevated temperatures. They are also suitable for heavy-duty applications that involve significant cutting forces. Ceramic inserts find application in specialized machining processes that require high-speed cutting, high-temperature resistance, or machining of hard-to-machine materials. They are commonly used in industries such as aerospace, automotive, and die/mold manufacturing. Ceramic inserts excel in cutting superalloys, hardened steels, and heat-resistant materials that would rapidly wear down carbide inserts. However, due to their brittleness, ceramics may not perform as well on softer materials and may require adjustments to machining parameters to avoid chipping or fracture. In summary, carbide inserts offer a combination of hardness, toughness, and wear resistance, making them versatile for a wide range of machining applications. They are suitable for cutting various materials and provide excellent tool life. Ceramic inserts, on the other hand, possess exceptional hardness, high-temperature resistance, and chemical stability. They excel in high-speed and high-temperature cutting scenarios, particularly with hard-to-machine materials. However, their brittleness requires careful handling and consideration of machining parameters. Selecting between carbide and ceramic inserts should be based on the specific machining requirements and material being cut. SQUARE INDEXABLE INSERT | Findbuytool

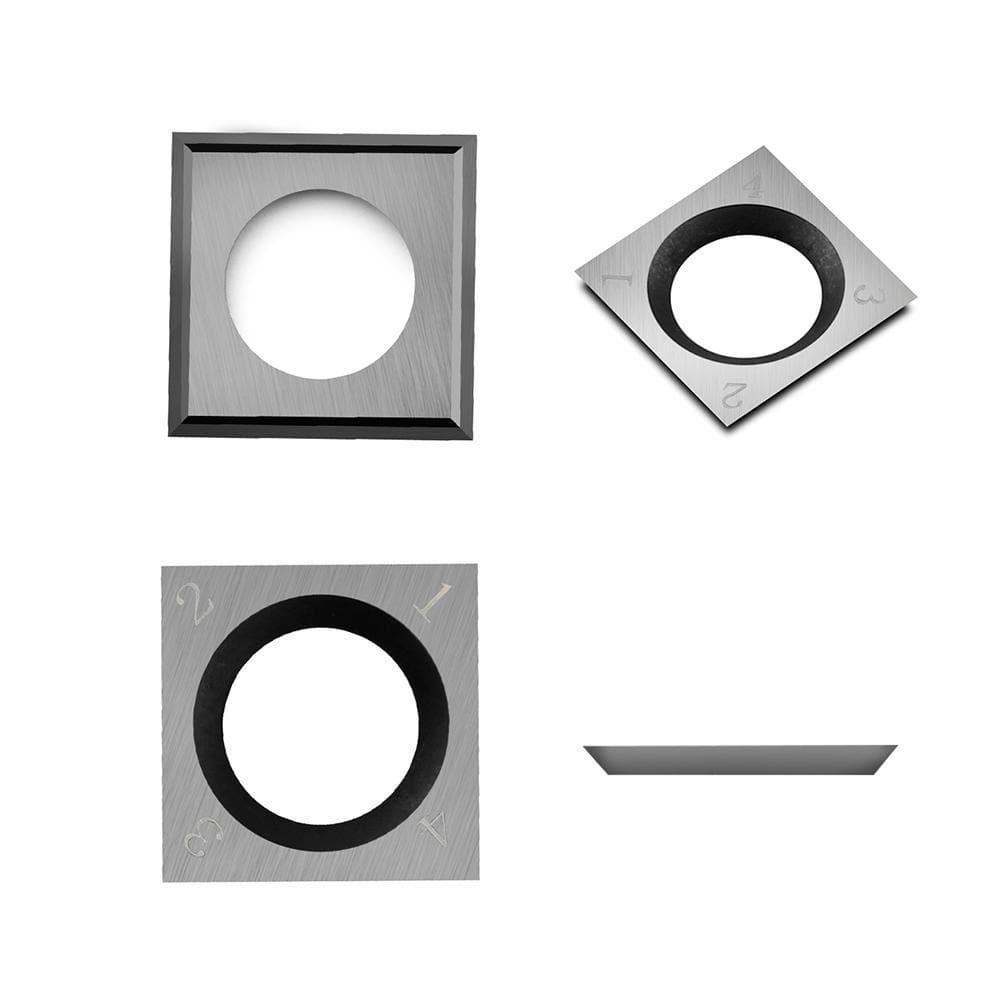

SQUARE INDEXABLE INSERT | Findbuytool